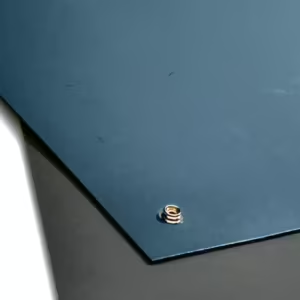

The ESD Anti-static Rubber Matting is 3mm depth to provide a safe, static-dissipative surface that prevents dangerous sparks in volatile or sensitive environments protecting equipment and operatives. It features a dual-layer construction: a conductive bottom layer and a static-dissipating top layer, ensuring reliable ESD protection as well as basic safety features such as slip resistance and high wear rating.

Key Features

Static dissipating synthetic Nitrile Butadiene Rubber (NBR)

Dissipating top layer

Electrical , chemical, and thermal resistance

For short and long term projects

Documentation

Case Studies & News

Case Studies & News

Read similar Case Study or News article

Certifications & Testing

Certifications & Testing

Surface resistivity or Tear Strength documents upon request

Typical Applications

- E-shops

- Clean Rooms

- Computer Rooms

- Precision Instruments

- Equipment Operation Rooms

- Sensitive Electrical Application

- Circuit Manufacturing

Installation

- Lifting: By hand

- Positioning: 1 person for fast offloading and handling

- Connectors: 10mm Grounding wire for ESD Matting

- Duration: Approx. 15-20 minutes for measuring, cutting, and laying it down (depending on site conditions)

- Storage/transport: Store the matting rolled up to avoid creases or folds

Benefits

![]() Protects sensitive electronics

Protects sensitive electronics

![]() Durable and flexible

Durable and flexible

![]() Resistant to chemicals and heat

Resistant to chemicals and heat

![]() Non-marking and easy to clean

Non-marking and easy to clean

![]() Avoid electrical damage

Avoid electrical damage

Sustainability & Compliance

- Reusable & Recyclable: Long-lasting and reusable

- Safety Standards: Complies with ESD safety standards

- Compliance: IEC 61340-5-1

Expert Insights

- Surface resistivity: Ω top layer : 107-109 Ω

- Resistance to a groundable point (Rgp): 6.5 x 10⁴ Ω

- Operating temperature: -30°C & +70°C

Need help choosing a mat for your purpose?

Need help choosing a mat for your purpose?

Our technical team can help you assess ground conditions, load requirements, and project logistics to recommend the best configuration.

Contact us for expert advice.

Services

Reviews

There are no reviews yet.